Ukuzinza Kwevolumu Okuhle kanye Nokumelana Nokushisa Kwe-Thermal, Ukuhlanzeka Okuphezulu kanye Ne-Refractoriness Tabular Alumina

- i-tabular alumina ta

- izinto ze-alumina ze-tabular

- i-alumina tabular

Incazelo emfushane

Ukwakheka Kwamakhemikhali

| Into | ukuhlanganisa | izinhlawulo | |||

| Inkomba | Okujwayelekile | Inkomba | Okujwayelekile | ||

| Ukwakheka kwamakhemikhali | I-Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| I-SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| I-Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| I-Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Izakhiwo Zomzimba

| Into | Inkomba | Okujwayelekile | |

| Izakhiwo Zomzimba | Ukuminyana kwenqwaba/cm3 | ≥3.50 | 3.58 |

| Ukumunca izinga lamanzi | ≤1.0% | 0.75 | |

| Izinga le-porosity | ≤4.0% | 2.6 | |

Impahla qhathanisa

| Into | I-Alumina yeTabular | I-White Fused Alumina | |

| Ukuqhathaniswa kwendawo ye-Tabular Alumina ne-White Fused Alumina | Ukwakheka kwamakhemikhali kwe-homogeneity | ukulingana | Inani eliphakeme kakhulu lama-Na2O |

| Usayizi wembotshana omaphakathi/μm | 0.75 | 44 | |

| Izinga le-Porosity/% | 3-4 | 5-6 | |

| Ukuminyana kwenqwaba/cm3 | 3.5-3.6 | 3.4-3.6 | |

| Ukuziphatha kwe-Creep/% | 0.88 | 0.04, ukuhlolwa okuphezulu | |

| Umsebenzi we-Sintering | Phezulu | phansi | |

| Amandla, ukumelana nokushaqeka okushisayo | Phezulu | phansi | |

| Izinga lokugqoka /cm3 | 4.4 | 8.7 | |

Ithebula namanye ama-Aggregate

Ama-aggregate awumgogodla wokubunjwa okuphikisayo futhi ahlinzeka ngokuzinza kobukhulu emikhiqizweni ephikisayo. Amafrakshini ama-coarser engeza ukushaqeka okushisayo kanye nokumelana nokugqwala futhi izinhlawulo ezihlanganisiwe zithuthukisa ukusatshalaliswa kosayizi wezinhlayiyana futhi andise ukuphikiswa komkhiqizo.

Ikhwalithi engaguquki ye-Tabular alumina ingumphumela wenqubo ye-sinter elawulwa kahle enamazinga okushisa okushisa angaphezu kuka-1800 ° C. Ukusetshenziswa kwezithando zokushisa eziphakeme ezinobuchwepheshe besimanje kuvumela ukuminyana kwezinto ezikhethiwe eziluhlaza ngaphandle kwezinsiza ze-sintering ezingase nomthelela omubi ezindaweni zokushisa eziphezulu ze-refractories.

Njengomphumela wenqubo ye-sinter, ama-aggregate abonisa ukwakheka okufanayo kwe-mineralogical kanye namakhemikhali kuzo zonke izingxenyana. Ngokuphambene nemikhiqizo ehlanganisiwe lapho ukungcola kunqwabelana khona ezinhlawulweni, ukusetshenziswa kwe-sintered aggregates ekwakhiweni kwe-refractory kuqinisekisa ukuziphatha okuzinzile nokuthembekile.

U-Junsheng unikeza amasayizi ahlukahlukene ama-aggregate ukusuka kumafrakshini amaholoholo ukuya kosayizi abacolekile abangu-<45 μm kanye no-<20 μm. Ukuchotshozwa nokugaya kulandelwa izinyathelo eziqinile zokususa ama-ayina eziholela ensimbi yamahhala ephansi kakhulu phakathi kwamafrakshini ahlukahlukene.

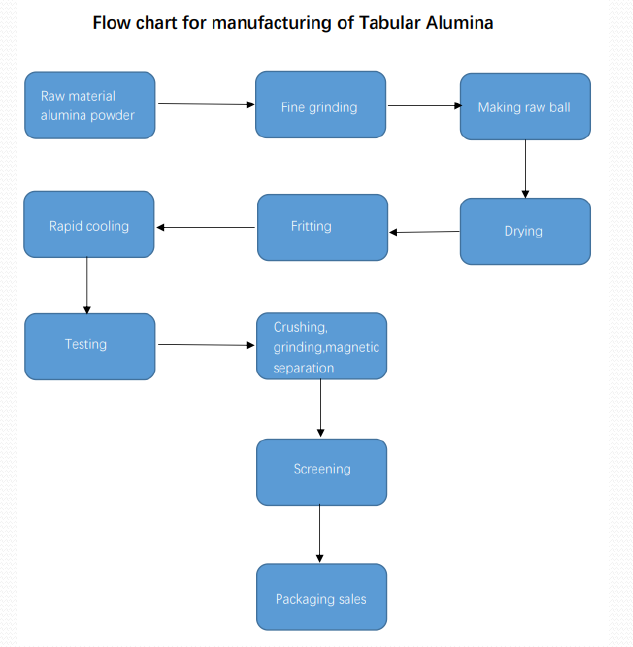

Inqubo Yokukhiqiza ye-Tabular alumina

I-alumina powder yempahla eluhlaza

Ukugaya kahle

Ukwenza ibhola elingahluziwe

Ukupholisa okusheshayo

I-Friting

Ukomisa

Ukuhlola

Ukugaya ukugaya ngokuhlukana kazibuthe

Ukuhlola

Ukuthengiswa kwamaphakheji

Isicelo Of Tabular Alumina

I-Tabular Alumina iyimpahla ekhethwayo kuzinza ezisebenza kahle ezingakakhiwe ezisetshenziswa ezimbonini ezihlukahlukene ezihlanganisa insimbi , isisekelo , usimende , ingilazi , i- prtrochemical , i-ceramic kanye nokushiswa kwemfucuza . Ezinye izinhlelo zokusebenza ezivamile ezinganqamuki zihlanganisa ukusetshenziswa kwayo kufenisha yomlilo kanye nokuhlunga kwensimbi.