I-Fused Alumina Zirconia, Az-25, Az-40

- i-zirconia alumina

- I-Zirconia-corundum

- ZA

Incazelo emfushane

Imininingwane

| BBrand Ukucaciswa | I-AZ-25 Inkomba | I-AZ-25 Inani Elijwayelekile | I-AZ-40 Inkomba | I-AZ-40 Inani Elijwayelekile |

| ZrO2 | 23%-27% | 24% | 38%-42% | 39% |

| Al2O3 | 72%imizuzu | 74% | 56%-60% | 59% |

| SiO2 | 0.8%ubuningi | 0.5% | 0.60% ubuningi | 0.4% |

| Fe2O3 | 0.3%ubuningi | 0.2% | 0.3%ubuningi | 0.15% |

| I-TiO2 | 0.8%ubuningi | 0.7% | 0.50%ubukhulu | 0.5% |

| I-CaO | 0.15% ubuningi | 0.14% | 0.15% ubuningi | 0.12% |

| Ukuminyana kwangempela (g/cm3) | 4.2 imiz | 4.23 | 4.6 imiz | 4.65 |

| Umbala | Gray noma Fresh gray | Gray noma Fresh gray | ||

Inqubo Yokukhiqiza Nesicelo

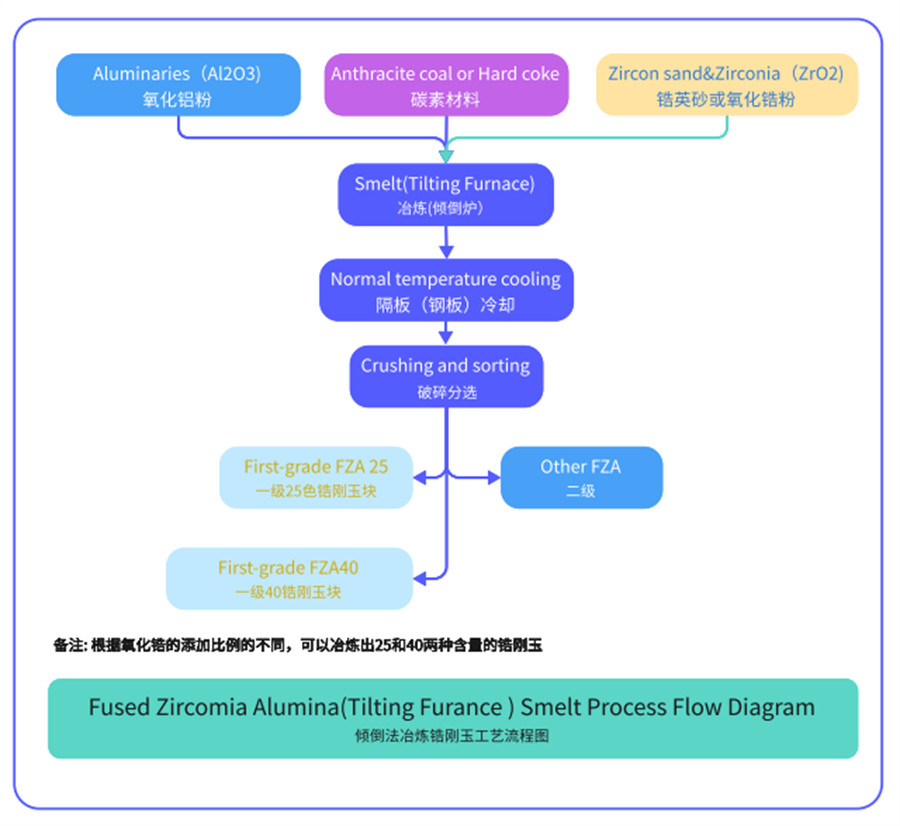

I-Fused Alumina--I-Zirconia ikhiqizwa esithandweni se-arc sikagesi esishisa kakhulu ngokuhlanganisa isihlabathi se-zirconium quartz ne-alumina. Ibonakala ngesakhiwo esiqinile nesiminyene, ukuqina okuphezulu, ukuzinza okuhle kokushisa. Ilungele ukukhiqiza amasondo amakhulu okugaya ensimbi kanye ne-Foundry snagging, amathuluzi amboziwe kanye nokuqhunyiswa kwamatshe, njll.

Iphinde isetshenziswe njengesengezo kuma-Continuous casting refractories. Ngenxa yokuqina kwayo okuphezulu isetshenziselwa ukunikeza amandla eMechanical kulawa ma-refractories.

I-Yttria-Tetragonal Zirconia Polycrystals (Y-TZP) ne-Alumina (Al2O3) idonse ukunakwa okubalulekile kobuchwepheshe bokufakelwa kwezinto ezibonakalayo ngenxa yokuhlanganiswa kwazo okuhle kwezakhiwo, njengokuqina okuphezulu, ukuqina kokuphuka, namandla aphezulu nokuqina , Lezi zici zizenzile. izinto ezikhangayo zohlelo olubanzi lwezinhlelo zokusebenza ezimboza uhla lwe-biomedical lapho evame ukusetshenziswa khona ezinsizeni zamazinyo njengama-abutments okufakelwa okufakelwa, amabhuloho, izigxobo zezimpande, nomqhele we-ceramic. Ngaphandle kwalokho, ziphinde zisetshenziswe ezinhlelweni zobunjiniyela ezahlukahlukene kufaka phakathi izinzwa ze-oxygen, i-thermal barrier coatings, amathuluzi okusika, izixhumi ze-fiber optical, namaseli kaphethiloli we-oxide aqinile. Kuyaphawuleka ukuthi ukuthuthukiswa kwezakhiwo zemishini ye-Y-TZP kubangelwa usayizi wayo wokusanhlamvu ocolekile noguquko lwesigaba se-tetragonal ukuya kwese-monoclinic. Lokhu kuguqulwa kwesigaba kuhambisana nokukhuphuka kwevolumu cishe ngo-3-5% okuholela ekuvimbeleni ukusakazeka kokuqhekeka futhi ngaleyo ndlela kuthuthukise ukuqina kwempahla. Nokho, kubalulekile ukuqaphela ukuthi lolu shintsho lungenzeka ngokuzenzakalelayo ngaphansi kwezimo ezithile. Uma i-zirconia ibhekene nezinga lokushisa eliphansi endaweni enomswakama ophakathi kuka-100 ℃ no-300 ℃, okungase kuholele ekuwohlokeni kwe-zirconia, okuholela ekuqineni nasekuqhekekeni okuncane. Lesi senzakalo saziwa ngokuthi ukuguga kwe-hydrothermal noma i-Low-Temperature Degradation (LTD) futhi ikhonjwe njengesici esinomthelela ekusebenzeni okuncishisiwe kwezingxenye ze-zirconia ekusetshenzisweni kwamathambo.

Abacwaningi baye bahlakulela izinhlanganisela eziningana lapho i-alumina ihlanganiswa khona nesakhiwo se-zirconia. Inhloso yalokhu kuhlanganiswa ukuthuthukisa ukumelana kwe-LTD kanye nokukhulisa izici ezihlukile zalezi zitsha zobumba ukuze kuthuthukiswe izakhiwo zemishini ye-tetragonal zirconia matrix Ngakolunye uhlangothi, ukuba khona kwe-alumina ku-matrix kudlala indima ebalulekile ekwakheni isakhiwo esiqinile esiza ekuvimbeleni izinhlayiya ze-zirconia. Ngesikhathi senqubo yokupholisa kusukela ekushiseni okushisayo, izinhlamvu ze-tetragonal zirconia zingangena ukuguqulwa kwesigaba kusukela esigabeni se-tetragonal kuya esigabeni se-monoclinic. Kulo mongo, i-alumina isebenza ukugcina okusanhlamvu kwe-zirconia esimweni esine-metastable, ukuvimbela ukuguqulwa okuphelele kwesigaba se-monoclinic. Lokhu kulondolozwa kwesigaba se-tetragonal kunomthelela ekuthuthukisweni okubonwayo ebukhuni bezinto zobumba

Mayelana Nokukhiqiza