Ukuzinza koMqulu oLungileyo kunye noKuxhathisa ukothuka kweThermal, ukucoceka okuPhezulu kunye neRefractoriness Tabular Alumina

- tabular alumina ta

- izixhobo zetabular alumina

- i-alumina tabular

Ingcaciso emfutshane

Ukuqulunqwa kwemichiza

| Into | i-aggregate | izohlwayo | |||

| Isalathiso | Isiqhelo | Isalathiso | Isiqhelo | ||

| Ukwakhiwa kweekhemikhali | Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Iipropati Zomzimba

| Into | Isalathiso | Isiqhelo | |

| Iipropati Zomzimba | Ubuninzi bobuninzi / cm3 | ≥3.50 | 3.58 |

| Ukufunxa izinga lamanzi | ≤1.0% | 0.75 | |

| Izinga le-Porosity | ≤4.0% | 2.6 | |

Ukuthelekisa ipropati

| Into | I-Alumina yeTabular | IAlumina eFused emhlophe | |

| Ukuthelekiswa kwepropati ye-Tabular Alumina kunye ne-White Fused Alumina | Ukubunjwa kweekhemikhali ze-homogeneity | ukulingana | I-Fine iphezulu kwi-Na2O |

| I-avareji yobungakanani bepore/μm | 0.75 | 44 | |

| Izinga lePorosity/% | 3-4 | 5-6 | |

| Ubuninzi bobuninzi / cm3 | 3.5-3.6 | 3.4-3.6 | |

| Ukuziphatha kwe-Creep/% | 0.88 | 0.04, uvavanyo oluphezulu | |

| Umsebenzi wokucula | Phezulu | phantsi | |

| Amandla, ukuxhathisa ukothuka kwe-thermal | Phezulu | phantsi | |

| Ireyithi yokunxiba /cm3 | 4.4 | 8.7 | |

Itheyibhile kunye nezinye iiAggregates

Ii-aggregates zingumqolo we-refractory formulation kwaye zibonelela ngozinzo lwe-dimensional kwiimveliso eziphikisayo. Amaqhezu anqabileyo ongeza ukothuka kwe-thermal kunye nokuxhathisa ukubola kwaye izohlwayo ezidibeneyo ziphucula ukusabalalisa ubungakanani beqhekeza kunye nokwandisa ukuchasana kwemveliso.

Umgangatho ohambelanayo we-alumina ye-Tabular yisiphumo senkqubo ye-sinter elawulwa kakuhle kunye namaqondo okushisa omlilo ngaphezu kwe-1800 ° C. Ukusetyenziswa kwezithando zokushisa eziphezulu kunye nobuchwepheshe bezobugcisa buvumela ukuxinaniswa kwezinto ezikhethiweyo ezikhethiweyo ngaphandle kokuncedisa i-sintering aid. impembelelo embi kwiipropati zokushisa eziphezulu ze-refractories.

Njengomphumo wenkqubo ye-sinter, i-aggregates ibonisa ukubunjwa okufanayo kwe-mineralogical kunye neekhemikhali kuwo onke amaqhezu. Ngokuchasene neemveliso ezidityanisiweyo apho ukungcola kuqokelelwa kwisohlwayo, ukusetyenziswa kwe-sintered aggregates kwi-refractory formulation iqinisekisa ukuziphatha okuzinzileyo nokuthembekileyo.

I-Junsheng ibonelela ngeesayithi ezahlukeneyo zeeaggregates ukusuka kumaqhezu arhabaxa kakhulu ukuya kubungakanani bomhlaba ocolekileyo we <45 μm kunye <20 μm. Ukutyumza kunye nokusila kulandelwa ngamanyathelo oku-de-ayina okunzulu okukhokelela kwi-iron ephantsi kakhulu phakathi kwamaqhezu ahlukeneyo.

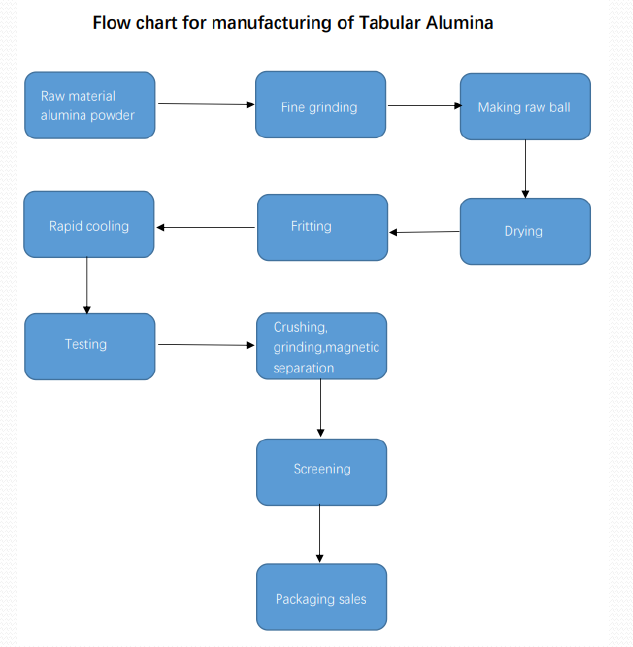

Inkqubo yeMveliso yeTabular alumina

Umgubo we-alumina wezinto ezikrwada

Ukusila kakuhle

Ukwenza ibhola ekrwada

Ukupholisa ngokukhawuleza

Ukuqhotsa

Ukomisa

Uvavanyo

Ukutyumza ukwahlukana kwamagnetic

Uvavanyo

Iintengiso zokupakisha

Ukusetyenziswa kweTabular Alumina

I-Tabular Alumina yimathiriyeli ekhethwayo kwii-refractories eziphezulu ezingasebenziyo ezisetyenziswa kumashishini ahlukeneyo aquka intsimbi, isiseko, i-samente, iglasi, i-protrochemical, i-ceramic, kunye nokutshisa inkunkuma. Ezinye izicelo eziqhelekileyo ezingezizo ezinqandayo ziquka ukusetyenziswa kwayo kwifenitshala ye-kiln kunye nokucoca isinyithi.