I-Fused Alumina Zirconia, Az-25, Az-40

- zirconia alumina

- Zirconia-corundum

- ZA

Ingcaciso emfutshane

Iinkcukacha

| BBrand Spec | I-AZ-25 Isalathiso | I-AZ-25 Ixabiso eliqhelekileyo | I-AZ-40 Isalathiso | I-AZ-40 Ixabiso eliqhelekileyo |

| ZrO2 | 23%-27% | 24% | 38%-42% | 39% |

| Al2O3 | 72% min | 74% | 56%-60% | 59% |

| SiO2 | 0.8% ubuninzi | 0.5% | 0.60% ubuninzi | 0.4% |

| Fe2O3 | 0.3% ubuninzi | 0.2% | 0.3% ubuninzi | 0.15% |

| TiO2 | 0.8% ubuninzi | 0.7% | 0.50% ubuninzi | 0.5% |

| CaO | 0.15% ubukhulu | 0.14% | 0.15% ubukhulu | 0.12% |

| Ubuninzi bokwenyani (g/cm3) | 4.2min | 4.23 | 4.6min | 4.65 |

| Umbala | Grey okanye Fresh ngwevu | Grey okanye Fresh ngwevu | ||

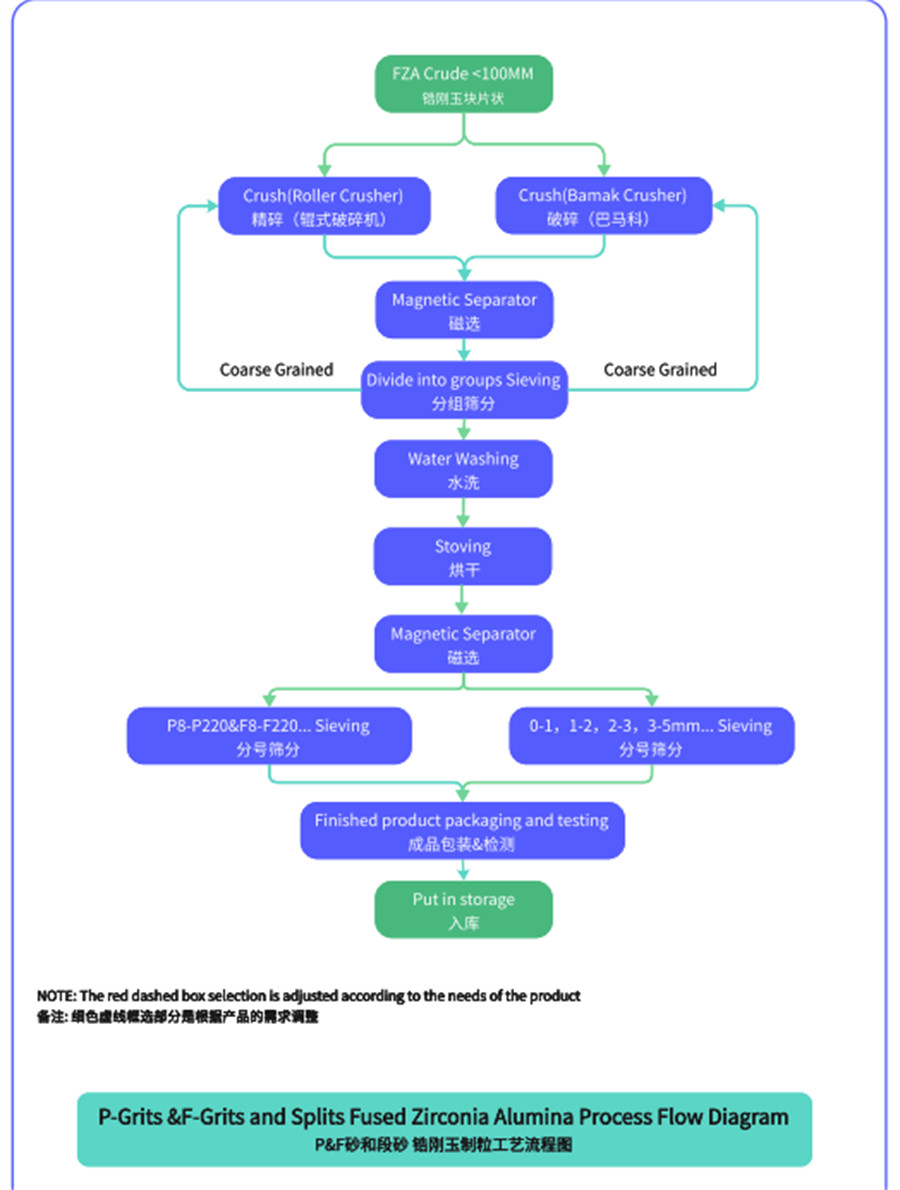

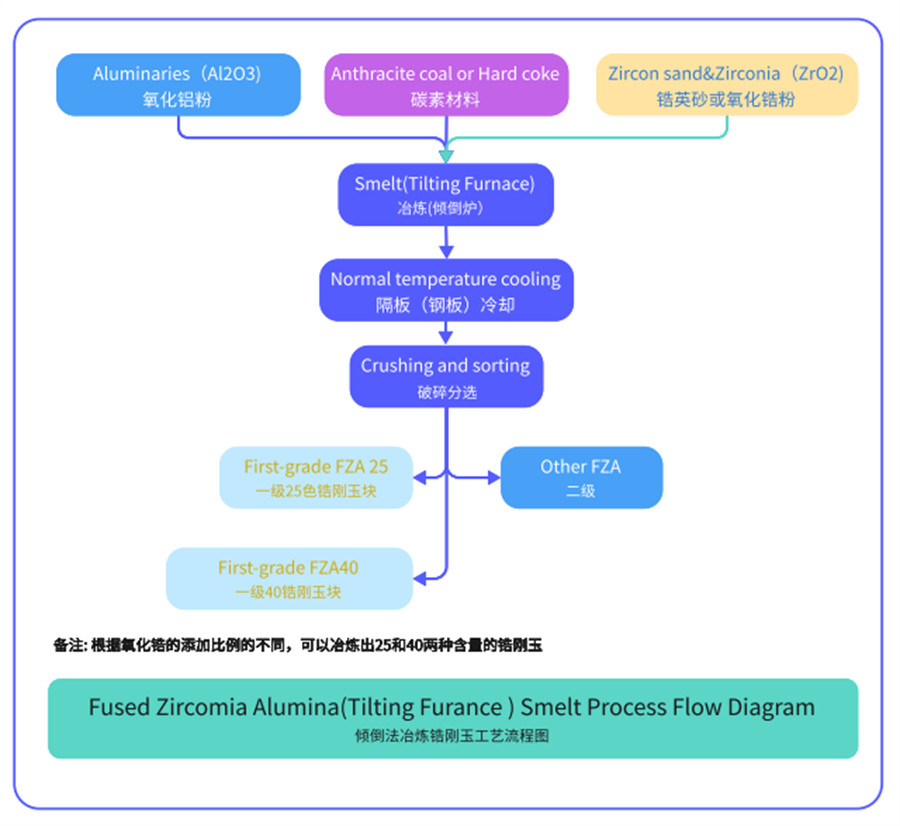

Inkqubo yeMveliso kunye nesicelo

I-Alumina eFused--I-Zirconia iveliswa kwisithando somlilo esiphakamileyo sombane ngokudibanisa isanti ye-quartz ye-zirconium kunye ne-alumina. Ibonakaliswe ngesakhiwo esinzima kunye nesixineneyo, ukuqina okuphezulu, ukuzinza okuhle kwe-thermal. Ilungele ukuvelisa amavili amakhulu okusila kwi-steel conditioning kunye ne-Foundry snagging, izixhobo ezigqunyiweyo kunye nokuqhushumba kwamatye, njl.

Ikwasetyenziswa njengesongezo kwi-Refractories yokuphosa ngokuqhubekayo. Ngenxa yokuqina kwayo okuphezulu isetyenziselwa ukunika amandla oMatshini kwezi refractories.

I-Yttria-Tetragonal Zirconia Polycrystals (Y-TZP) kunye ne-Alumina (Al2O3) zitsale ingqalelo ebalulekileyo kubuchwepheshe bokufakelwa kwezinto ngenxa yokudityaniswa kwazo okugqwesileyo, njengokuqina okuphezulu, ukuqina kokwaphuka, kunye namandla aphezulu kunye nokuqina. izixhobo ezinomtsalane kuluhlu olubanzi lwezicelo ezigubungela uluhlu lwebhayoloji apho lusetyenziswa rhoqo kwizicelo zamazinyo ezinje ngokufakelwa kweprosthetic, iibhulorho, izithuba zeengcambu, kunye nesithsaba seceramic. Ngaphandle koko, zikwasetyenziswa kwizicelo zobunjineli ezahlukeneyo ezibandakanya izinzwa zeoksijini, izithintelo zomqobo ezishushu, izixhobo zokusika, izihlanganisi zefiber optical, kunye neeseli eziqinileyo ze-oxide. Kubalulekile ukuqaphela ukuba ukuphuculwa kweempawu zoomatshini ze-Y-TZP kubalelwa kubungakanani bayo obucolekileyo obuziinkozo kunye ne-tetragonal ukuya kwinguqu yesigaba se-monoclinic. Esi sigaba senguqu sikhatshwa kukunyuka komthamo omalunga ne-3–5% okukhokelela ekuthinteleni ukwanda kokuqhekeka kwaye oko konyusa ukuqina kwemathiriyeli. Nangona kunjalo, kubalulekile ukuqaphela ukuba olu tshintsho lunokwenzeka ngokuzenzekelayo phantsi kweemeko ezithile. Ukuba i-zirconia ibonakaliswe kubushushu obuphantsi kwindawo efumileyo ephakathi kwe-100 ℃ kunye ne-300 ℃, enokuthi ikhokhelele ekuwohlokeni kwe-zirconia, okukhokelela ku-roughening kunye ne-microcracking. Le nto yaziwa ngokuba yi-hydrothermal aging okanye i-Low-Temperature Degradation (LTD) kwaye ichongiwe njengento enegalelo ekunciphiseni ukusebenza kwamacandelo e-zirconia kwizicelo ze-orthopedic.

Abaphandi baye baqulunqa iimbumba ezininzi apho i-alumina ifakwe kwisakhiwo se-zirconia. Injongo yolu kudityaniswa kukuphucula ukuxhathisa kwe-LTD kunye nokongamela iimpawu ezikhethekileyo zezi zeseramics ukuphucula iimpawu zomatshini we-tetragonal zirconia matrix Kwelinye icala, ubukho be-alumina kwi-matrix budlala indima ebalulekileyo ekudaleni i-matrix. isakhiwo esiqinileyo esinceda ukunyanzelisa i-zirconia particles. Ngexesha lenkqubo yokupholisa ukusuka kwiqondo lokushisa elitshisayo, iinkozo ze-tetragonal zirconia zinokungena kwinguqu yesigaba ukusuka kwisigaba se-tetragonal ukuya kwisigaba se-monoclinic. Kulo mxholo, i-alumina isebenza ukugcina iinkozo ze-zirconia kwi-metastable state, ukukhusela ukuguqulwa okupheleleyo kwisigaba se-monoclinic. Oku kugcinwa kwesigaba se-tetragonal kuncedisa ekuphuculeni okubonwayo kubulukhuni bezinto ze-ceramic

Malunga neMveliso