Kateguhan Optimal tina Biji-bijian Brown Fused Alumina, Suite Pikeun Abrasives sareng Refractorie

- Aluminium oksida coklat

- BFA

- Corundum coklat

Pedaran pondok

Aplikasi

Brown Fused Alumina mangrupikeun abrasive anu seukeut, anu cocog pisan pikeun ngagiling logam anu kakuatan tegangan tinggi. Sipat termalna ngajantenkeun bahan anu saé pikeun dianggo dina pabrik produk refractory. Bahan ieu ogé dianggo dina aplikasi sanés sapertos blasting sareng pengerasan permukaan.

| Kelas | Spésifikasi | Komposisi Kimia (F46) | ||||

| Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | ||

| Kelas Bata * | 0-1,1-3,3-5mm-8+16,-16+30,-30+60 bolong, Denda | ≥95.2 | ≤1.0 | ≤0.3 | ≤3.0 | ≤0.4 |

| Kelas Castable | 0-1,1-3,3-5mm-8+16,-16+30,-30+60 bolong, Denda | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Kelas Vitrified | F12-F220 | ≥95.5 | ≤1.0 | ≤0.3 | 2.2-3.0 | ≤0.4 |

| Résin & Blasting Kelas | F12-F220 | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Kelas Mikro | P240-P1200 | ≥92-95 | ≤1.0-1.8 | ≤0.3-0.5 | ≤2.2-4.5 | - |

| F240-F1000 | ≥88-95 | ≤1.0-2.5 | ≤0.3-0.5 | ≤2.2-6.5 | - | |

| Titik lebur | 2050 ℃ | |||||

| Refractoriness | 1980 ℃ | |||||

| Kapadetan leres | 3,90 ming/cm3 | |||||

| Mohs karasa | 9.00 mnt | |||||

| Barang | Ukuran | Komposisi Kimia (%) | ||||

| Al2O3 | TiO2 | CaO | SiO2 | Fe2O3 | ||

| A jeung AP1 | F4~F80 P12~P80 | 95.00~97.50 | 1.70~3.40 | ≤0.42 | ≤1.00 | ≤0.30 |

| F90~F150 P100~P150 | 94.50~97.00 | |||||

| F180~F220 P180~P220 | 94.00–97.00 | 1.70~3.60 | ≤0,45 | ≤1.00 | ≤0.30 | |

| F230~F800 (P240~P800)) | ≥93,50 | 1.70~3.80 | ≤0,45 | ≤1.20 | ≤0.30 | |

| F1000~F1200 (P1000~P1200) | ≥93.00 | ≤4.00 | ≤0.50 | ≤1.40 | ≤0.30 | |

| P1500~P2500 | ≥92,50 | ≤4.20 | ≤0,55 | ≤1,60 | ≤0.30 | |

| AB jeung AP2 | F4~F80 P12~P80 | ≥94.00 | 1.50~3.80 | ≤0,45 | ≤1.20 | ≤0.30 |

| F90~F220 P100~P220 | ≥93.00 | 1.50~4.00 | ≤0.50 | ≤1.40 | - | |

| F230~F800 (P240~P800) | ≥92,50 | ≤4.20 | ≤0.60 | ≤1,60 | - | |

| F1000~F1200 (P1000~P1200) | ≥92.00 | ≤4.20 | ≤0.60 | ≤1,80 | - | |

| P1500~P2500 | ≥92.00 | ≤4,50 | ≤0.60 | ≤2.00 | - | |

| AS | 16~220 | ≥93.00 | - | - | - | - |

Bata / Vitrified Kelas BFA: Dihasilkeun ngagunakeun Bauxite kelas husus dina parameter fusi dikawasa. Kelas ieu cocog pikeun bata / produk Vitrified nyegah retakan / Fissures, liang jeung bintik Hideung dina produk ahir.

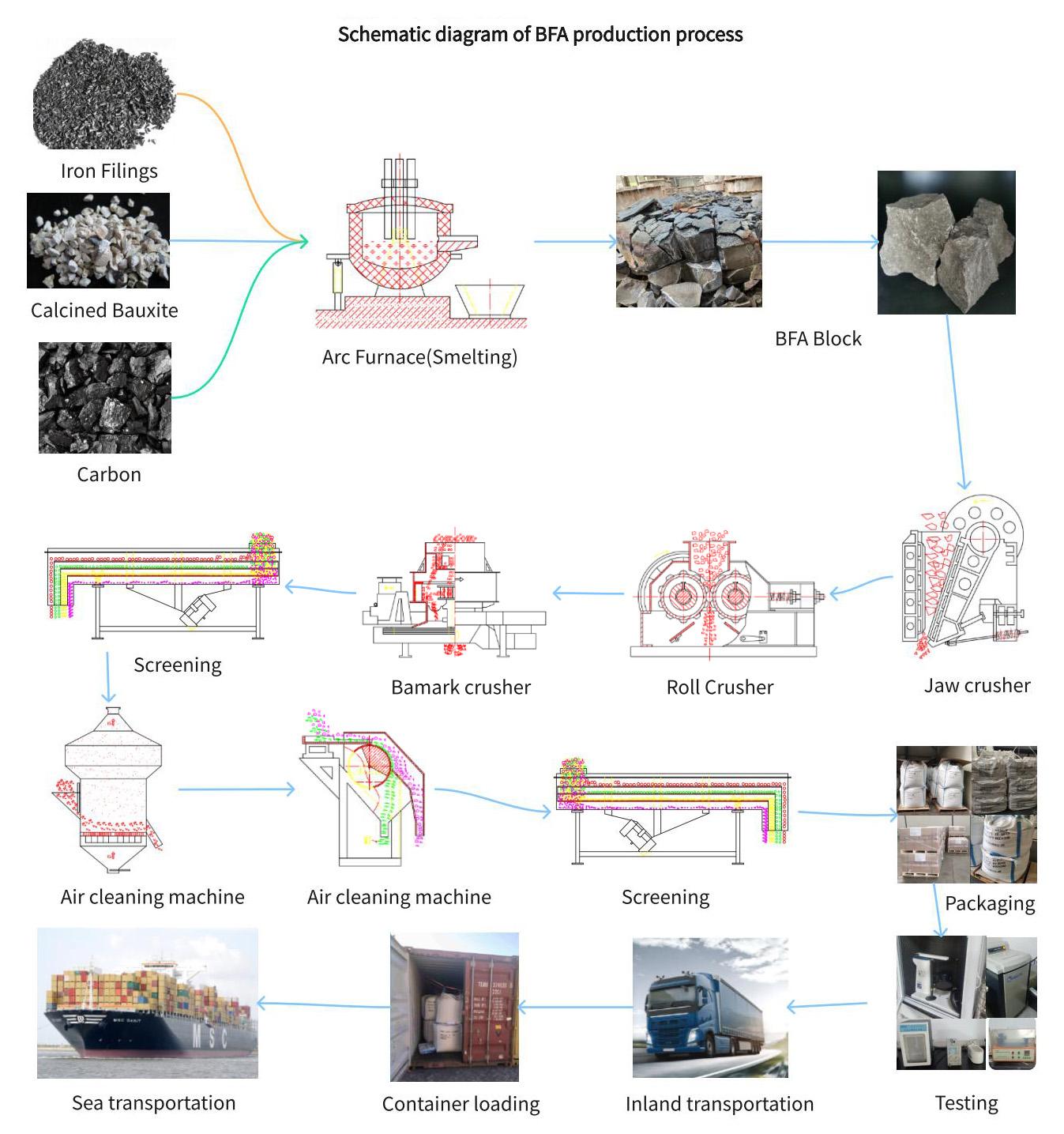

Prosés Produksi

Brown Fused Alumina dihasilkeun ku peleburan Bauksit Kalsinasi dina tungku busur listrik dina suhu leuwih ti 2000°C. Prosés solidifikasi slow nuturkeun fusi, pikeun ngahasilkeun kristal blocky. The lebur pitulung dina miceun residual walirang jeung karbon, kontrol ketat leuwih tingkat Titania salila prosés fusi ensures kateguhan optimum tina séréal.

Lajeng atah tiis ieu salajengna ditumbuk, cleaned tina najis magnét dina inténsitas tinggi separators magnét sarta digolongkeun kana fraksi ukuran sempit pikeun nyocogkeun pamakéan tungtung. garis dedicated ngahasilkeun produk pikeun aplikasi béda.