Botsitso bo Botle ba Bolumo le Ho hanyetsa Mocheso oa Thermal Shock, Bohloeki bo Phahameng le Refractoriness Tabular Alumina

- alumina tabular ta

- lisebelisoa tsa aluminium tsa tabular

- aluminium tabular

Tlhaloso e Khutšoane

Sebopeho sa Lik'hemik'hale

| Ntho | aggregate | likotlo | |||

| Index | E tloaelehileng | Index | E tloaelehileng | ||

| Sebopeho sa lik'hemik'hale | Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Thepa ea 'Mele

| Ntho | Index | E tloaelehileng | |

| Thepa ea 'Mele | Boima ba Bongata/cm3 | ≥3.50 | 3.58 |

| Sekhahla sa ho noa metsi | ≤1.0% | 0.75 | |

| Sekhahla sa porosity | ≤4.0% | 2.6 | |

Thepa bapisa

| Ntho | Tabular Alumina | White Fused Alumina | |

| Thepa e bapisoang le Tabular Alumina le White Fused Alumina | Motsoako oa lik'hemik'hale oa homogeneity | tekano | Fine e phahame ho Na2O |

| Karolelano ea boholo ba pore/μm | 0.75 | 44 | |

| Porosity rate/% | 3-4 | 5-6 | |

| Boima ba Bongata/cm3 | 3.5-3.6 | 3.4-3.6 | |

| Creep Behaviour/% | 0.88 | 0.04, teko e phahameng | |

| Ts'ebetso ea sintering | Phahameng | tlase | |

| Matla, ho hanyetsa mocheso oa mocheso | Phahameng | tlase | |

| Sekhahla sa ho roala /cm3 | 4.4 | 8.7 | |

Tabular le li-Aggregates tse ling

Li-aggregates ke mokokotlo oa sebopeho sa refractory 'me li fana ka botsitso bo boholo ho lihlahisoa tsa refractory. Likaroloana tse mahoashe li eketsa ho ts'oha ha mocheso le ho hanyetsa kutu 'me likotlo tse kopaneng li ntlafatsa kabo ea boholo ba likaroloana le ho eketsa boits'oaro ba sehlahisoa.

Boleng bo tsitsitseng ba Tabular alumina ke phello ea ts'ebetso ea sinter e laoloang hantle e nang le mocheso oa ho chesa ka holimo ho 1800 ° C. Tšebeliso ea libopi tsa mocheso o phahameng ka theknoloji ea morao-rao e lumella ho teteka ha thepa e tala e khethiloeng ntle le lithuso tsa sintering tse neng li tla etsa joalo. e ama hampe thepa e phahameng ea mocheso oa li-refractories.

Ka lebaka la ts'ebetso ea sinter, li-aggregates li bonts'a motsoako o tšoanang oa mineralogical le oa lik'hemik'hale bakeng sa likaroloana tsohle. Ho fapana le lihlahisoa tse kopantsoeng moo litšila li bokellanang likotlong, tšebeliso ea sintered aggregates ka mokhoa oa refractory e tiisa boitšoaro bo tsitsitseng le bo ka tšeptjoang.

Junsheng e fana ka litekanyo tse fapaneng tsa likarolo ho tloha ho likaroloana tse mahoashe ho isa ho tsa boholo bo botle ba <45 μm le <20 μm. Ho pshatla le ho sila ho lateloa ke mehato e matla ea ho tlosa tšepe e hlahisang tšepe e tlase haholo ka har'a likaroloana tse fapaneng.

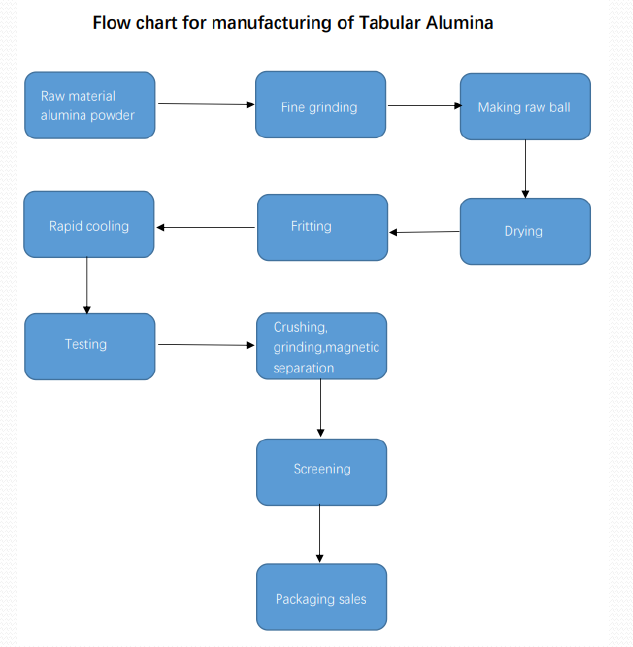

Ts'ebetso ea Tlhahiso ea Tabular alumina

Lisebelisoa tse tala tsa alumina phofo

Ho sila hantle

Ho etsa bolo e tala

Pholiso e potlakileng

Ho hlatsa

Ho omisa

Teko

Ho senya ho sila karohano ea makenete

Tlhahlobo

Thekiso ea liphutheloana

Tšebeliso ea Tabular Alumina

Tabular Alumina ke thepa ea khetho ho li-refractories tse phahameng tsa ts'ebetso tse se nang sebopeho tse sebelisoang liindastering tse fapaneng tse kenyelletsang tšepe, setsi sa motheo, samente, khalase, prtrochemical, ceramic, le litšila tse chesitsoeng. Lisebelisoa tse ling tse tloaelehileng tse sa refractory li kenyelletsa tšebeliso ea eona ka har'a thepa ea ka tlung le bakeng sa ho hloekisa tšepe.