Deganaanshaha Mugga Wanaagsan iyo Caabbinta Shock kulaylka, Nadiif Sarreysa iyo Dib-u-soo-celinta Alumina

- aluminium tabular ta

- qalabka aluminium ee tabular

- aluminium tabular

Sharaxaad Gaaban

Halabuurka Kiimikada

| Shayga | wadar ahaan | ganaax | |||

| Tusmada | Caadiyan | Tusmada | Caadiyan | ||

| Halabuurka kiimikada | Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Guryaha Jirka

| Shayga | Tusmada | Caadiyan | |

| Guryaha Jirka | Cufnaanta weyn/cm3 | ≥3.50 | 3.58 |

| nuugista heerka biyaha | ≤1.0% | 0.75 | |

| Heerka liidashada | ≤4.0% | 2.6 | |

Isbarbardhigga hantida

| Shayga | Aluminium-tabuleed | Aluminium-cadi ah oo isku dhafan | |

| Isbarbardhigga Hantida Alumina-ta Tabular iyo Alumina Fused Cad | Halabuurka kiimikaad ee isku midka ah | sinnaanta | Ganaaxdu aad bay ugu sarraysaa Na2O |

| Celceliska cabbirka daloolka/μm | 0.75 | 44 | |

| Heerka liidata/% | 3-4 | 5-6 | |

| Cufnaanta weyn/cm3 | 3.5-3.6 | 3.4-3.6 | |

| Dhaqanka gurracan/% | 0.88 | 0.04, imtixaan sare | |

| Dhaqdhaqaaqa dheesha | Sare | hooseeya | |

| Xoog, caabbinta shoogga kulaylka | Sare | hooseeya | |

| Heerka xirashada /cm3 | 4.4 | 8.7 | |

Tabular & Isku-darka kale

Isku-darku waa laf-dhabarta habaynta dib-u-soo-celinta waxayna bixiyaan xasillooni cabbir ah alaabada dib-u-celinta. Jajabyada qallafsan waxay ku daraan shoogga kulaylka iyo iska caabinta daxalka iyo ganaaxyada wadarta guud waxay hagaajiyaan qaybinta cabbirka walxaha waxayna kordhiyaan refractoriness ee alaabta.

Tayada joogtada ah ee alumina Tabular waa natiijada habka sinter-ka si fiican loo xakameeyo oo leh heerkulka dabka ee ka sarreeya 1800 ° C. Isticmaalka foornooyinka heerkulka sare leh ee tiknoolajiyada casriga ah waxay oggolaataa cufnaanta alaabta ceeriin ee la doortay iyada oo aan la helin qalab qalabayn kara si xun u saameeya sifooyinka heerkulka sare ee refractories.

Natiijadu tahay habka sinter-ka, isku-darka isku-darka ah waxay soo bandhigaan isku mid ah macdanta iyo kiimikada dhammaan jajabyada. Ka soo horjeeda alaabooyinka isku dhafan ee wasakhdu ku ururto ganaaxyada, isticmaalka isku-darka isku-darka ah ee qaabaynta diidmada waxay dammaanad qaadaysaa dabeecad xasilloon oo la isku halayn karo.

Junsheng waxay bixisaa qiyaaso kala duwan oo isku geyn ah laga bilaabo jajabyo aad u qallafsan ilaa cabbirro dhul-gaaban oo <45 μm iyo <20 μm. Burburinta iyo shiididda waxaa raacda tillaabooyinka birta-dhigista degdega ah taas oo keenta in birta bilaashka ah ay aad u yar tahay gudaha jajabyada kala duwan.

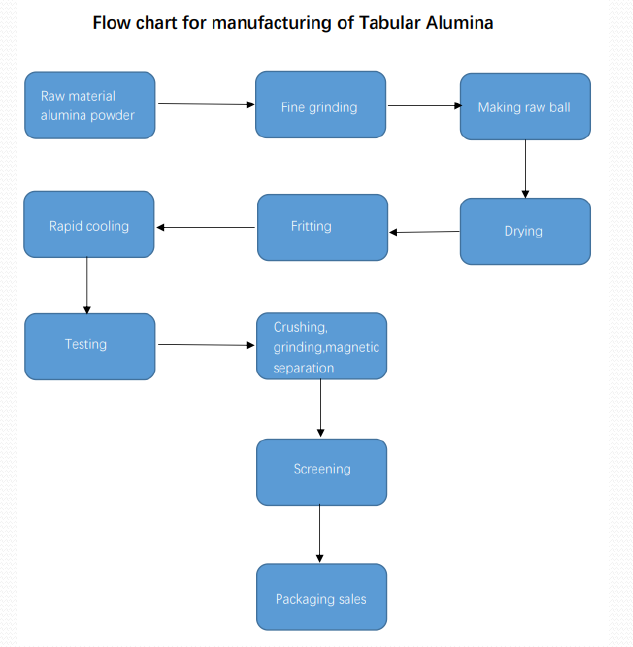

Habka wax-soo-saarka ee aluminiinta Tabular

Budada aluminium ee alaabta ceeriin

Shiidi wanaagsan

Samaynta kubbad cayriin

Qaboojin degdeg ah

Duubista

Qalajinta

Tijaabinta

Burburinta shiidida kala soocida magnetic

Baaritaanka

Baakadaha iibka

Codsiga Aluminiinka Tabular

Tabular Alumina waa shayga doorashada ee dib-u-celinta waxqabadka sare ee aan qaabaysanayn ee loo isticmaalo warshado kala duwan oo ay ka mid yihiin birta , faashadaha , sibidhka , galaaska , kiimikaad , dhoobada , iyo gubida qashinka . Codsiyada kale ee caadiga ah ee aan leexleexeynin waxaa ka mid ah isticmaalka alaabta guriga iyo sifeynta birta.