Yakanaka Vhoriyamu Kugadzikana uye Thermal Shock Resistance, Kuchena Kwepamusoro uye Refractoriness Tabular Alumina

- tabular alumina ta

- tabular alumina zvinhu

- alumina tabular

Tsanangudzo Pfupi

Kuumbwa Kwemakemikari

| Item | aggregate | fines | |||

| Index | Typical | Index | Typical | ||

| Kemikari yakagadzirwa | Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Zvinhu Zvenyama

| Item | Index | Typical | |

| Zvinhu Zvenyama | Bulk Density/cm3 | ≥3.50 | 3.58 |

| Kutora chiyero chemvura | ≤1.0% | 0.75 | |

| Porosity rate | ≤4.0% | 2.6 | |

Property enzanisa

| Item | Tabular Alumina | White Fused Alumina | |

| Property enzanisa yeTabular Alumina uye White Fused Alumina | Kemikari yakagadzirwa yehomogeneity | kuenzana | Fine yakakwira muNa2O |

| Avhareji yemboro saizi/μm | 0.75 | 44 | |

| Porosity rate/% | 3-4 | 5-6 | |

| Bulk Density/cm3 | 3.5-3.6 | 3.4-3.6 | |

| Creep Behaviour/% | 0.88 | 0.04, yepamusoro-bvunzo | |

| Sintering chiitiko | High | low | |

| Simba, thermal shock resistance | High | low | |

| Chiyero chekupfeka /cm3 | 4.4 | 8.7 | |

Tabular uye mamwe maAggregates

Aggregates ndiwo musana wekuumbwa kwerefractory uye inopa kugadzikana kwedimensional kune zvigadzirwa zvinoramba. Iwo akaomesesa mafractions anowedzera kupisa kutyisa uye corrosion kuramba uye mafiindi akaunganidzwa anogonesa kugovera saizi yechikamu uye anowedzera kuramba kwechigadzirwa.

Unhu hunopindirana hweTabular alumina ndiyo mhedzisiro yeinodzorwa zvakanaka sinter process ine kupisa kwekushisa kunopfuura 1800 ° C. Kushandiswa kwekushisa kwekushisa kwepamusoro nehunyanzvi hwemazuva ano kunobvumira densification yezvinhu zvakasarudzwa zvakasvibirira pasina sintering aids iyo inogona. zvinokanganisa zvakanyanya kupisa kwekushisa kweiyo refractories.

Nekuda kweiyo sinter process, iwo akaunganidzwa anoratidza yakafanana mineralogical uye makemikari kuumbwa kwezvikamu zvese. Kupesana nezvigadzirwa zvakasanganiswa apo tsvina inoungana mufaindi, kushandiswa kwe sintered aggregates mukugadzira refractory kunovimbisa kugadzikana uye kuvimbika maitiro.

Junsheng inopa masaizi akasiyana-siyana ezvikamu kubva kune zvakakasharara kusvika kune akatsetseka-pasi saizi ye <45 μm uye <20 μm. Kupwanya uye kugaya kunoteverwa neyakaomesesa de-ironing matanho anokonzeresa yakaderera yemahara iron mukati mezvikamu zvakasiyana.

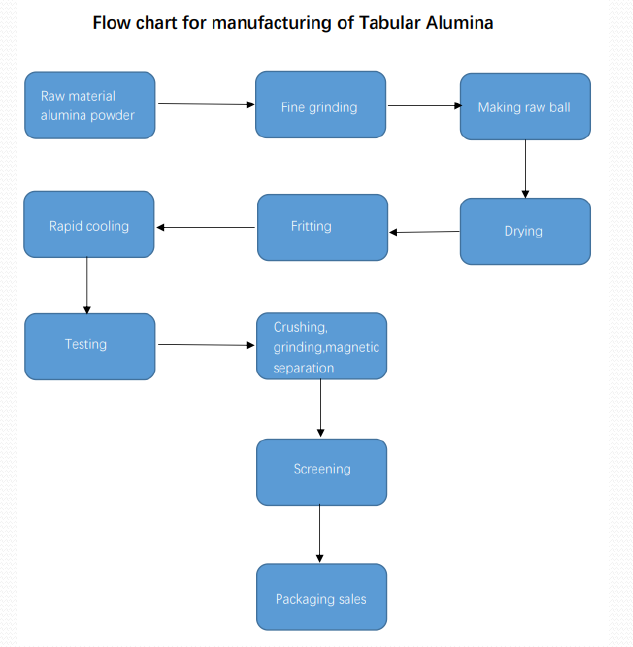

Kugadzira Maitiro eTabular alumina

Raw material alumina poda

Kukuya zvakanaka

Kuita bhora mbishi

Kukurumidza kutonhora

Friting

Kuomesa

Testing

Kupwanya kugaya magnetic separation

Kuongorora

Packaging sales

Kushandiswa kweTabular Alumina

Tabular Alumina ndicho chinhu chesarudzo mune isina kuumbwa yakakwira performance refractories inoshandiswa mumaindasitiri akasiyana siyana anosanganisira simbi , foundry , simende , girazi , prtrochemical , ceramic , uye tsvina incineration . Zvimwe zvakajairika zvisiri-refractory application zvinosanganisira kushandiswa kwayo muchoto fenicha uye nekusefa kwesimbi.