Kukhazikika Kwabwino Kwa Voliyumu Ndi Kukaniza Kugwedezeka Kwamatenthedwe, Kuyera Kwambiri Ndi Kukaniza Tabular Alumina

- aluminiyamu tabular ta

- tabular aluminiyamu zipangizo

- aluminiyamu tabular

Kufotokozera Kwachidule

Chemical Composition

| Kanthu | kuphatikiza | chindapusa | |||

| Mlozera | Chitsanzo | Mlozera | Chitsanzo | ||

| Chemical zikuchokera | Al2O3 (%) | ≥99.20 | 99.5 | ≥99.00 | 99.5 |

| SiO2 (%) | ≤0.10 | 0.06 | ≤0.18 | 0.08 | |

| Fe2O3 (%) | ≤0.10 | 0.07 | ≤0.15 | 0.09 | |

| Na2O (%) | ≤0.40 | 0.28 | ≤0.40 | 0.30 | |

Zakuthupi

| Kanthu | Mlozera | Chitsanzo | |

| Zakuthupi | Kuchulukana kwakukulu/cm3 | ≥3.50 | 3.58 |

| Kuchuluka kwa madzi | ≤1.0% | 0.75 | |

| Porosity mlingo | ≤4.0% | 2.6 | |

Kuyerekeza katundu

| Kanthu | Tabular aluminiyamu | White Fused Alumina | |

| Katundu poyerekeza ndi Tabular Alumina ndi White Fused Alumina | Chemical zikuchokera homogeneity | kufanana | Fine ili pamwamba pa Na2O |

| Avereji ya pore kukula/μm | 0.75 | 44 | |

| Porosity rate/% | 3-4 | 5-6 | |

| Kuchulukana kwakukulu/cm3 | 3.5-3.6 | 3.4-3.6 | |

| Makhalidwe Olakwika/% | 0.88 | 0.04, mayeso apamwamba | |

| Sintering ntchito | Wapamwamba | otsika | |

| Mphamvu, kukana kutentha kwa kutentha | Wapamwamba | otsika | |

| Mlingo wa kuvala /cm3 | 4.4 | 8.7 | |

Tabular & Aggregates ena

Aggregates ndi msana wa mapangidwe refractory ndi kupereka dimensional bata kwa mankhwala refractory. Tizigawo ta coarser kuwonjezera matenthedwe mantha ndi dzimbiri kukana ndi akaphatikiza chindapusa konza tinthu kukula kugawa ndi kuonjezera refractoriness wa mankhwala.

Ubwino wokhazikika wa Tabular alumina ndi zotsatira za ndondomeko yoyendetsedwa bwino ya sinter ndi kutentha kwa kutentha pamwamba pa 1800 ° C. Kugwiritsira ntchito ng'anjo zotentha kwambiri ndi teknoloji yamakono kumalola kusakanikirana kwa zipangizo zosankhidwa popanda zothandizira zomwe zingapangitse kumakhudza kwambiri kutentha katundu wa refractories.

Chifukwa cha ndondomeko ya sinter, ma aggregates amawonetsa kufanana kwa mineralogical ndi mankhwala kwa zigawo zonse. Mosiyana ndi zinthu zosakanizidwa zomwe zonyansa zimachulukana mu chindapusa, kugwiritsa ntchito sintered aggregates popanga refractory kumatsimikizira khalidwe lokhazikika komanso lodalirika.

Junsheng amapereka masanjidwe osiyanasiyana ophatikizika kuchokera kuzigawo zowoneka bwino kwambiri mpaka kukula bwino kwa <45 μm ndi <20 μm. Kuphwanyidwa ndi mphero kumatsatiridwa ndi njira zochepetsera-ironi zomwe zimapangitsa kuti chitsulo chaulere chikhale chochepa kwambiri m'magulu osiyanasiyana.

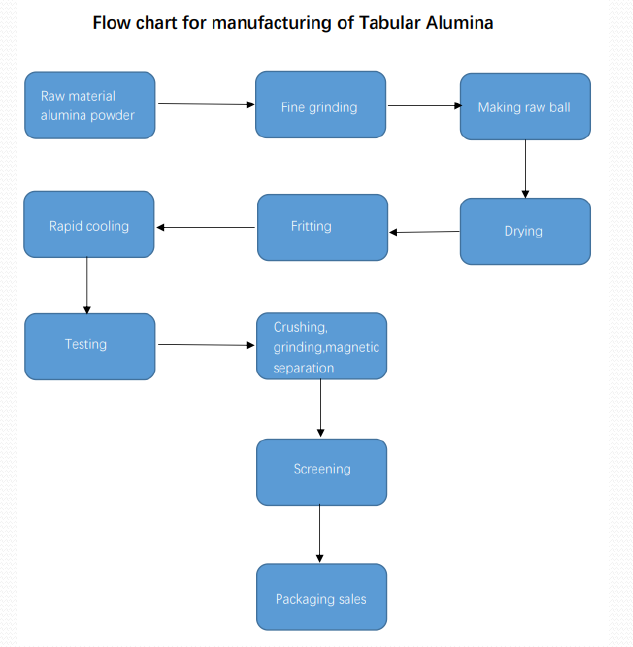

Njira Yopangira Tabular alumina

Zopangira alumina ufa

Akupera bwino

Kupanga mpira wakuda

Kuzizira kofulumira

Friting

Kuyanika

Kuyesa

Kuphwanya akupera maginito kulekana

Kuwunika

Zogulitsa zamapaketi

Kugwiritsa Ntchito Tabular Alumina

Tabular Alumina ndi chinthu chomwe chimasankhidwa m'mafakitale osawoneka bwino omwe amagwiritsidwa ntchito m'mafakitale osiyanasiyana monga chitsulo, maziko, simenti, magalasi, prtrochemical, ceramic, ndi kuyatsa zinyalala. Ntchito zina zodziwika bwino zosakanizidwa ndizomwe zimagwiritsidwa ntchito pamipando yamoto komanso kusefera zitsulo.