Zoo Volume Stability Thiab Thermal Shock Resistance, Siab Purity Thiab Refractoriness Tabular Alumina

- tabular alumina ta

- tabular alumina cov ntaub ntawv

- alumina tabular

Qhia luv luv

Tshuaj muaj pes tsawg leeg

| Yam khoom | tag nrho | raug nplua | |||

| Index | Hom | Index | Hom | ||

| Tshuaj muaj pes tsawg leeg | Al2O3 (%) | ≥99.20 | 99.5 ua | ≥99.00 Nws | 99.5 ua |

| SiO2 (%) | ≤ 0.10 | 0.06 ib | ≤ 0.18 | 0.08 ib | |

| Fe2O3 (%) | ≤ 0.10 | 0.07 ib | ≤ 0.15 | 0.09 ib | |

| Na2O (%) | ≤ 0.40 | 0.28 ib | ≤ 0.40 | 0.30 Nws | |

Lub cev muaj zog

| Yam khoom | Index | Hom | |

| Lub cev muaj zog | Qhov ntom ntom / cm3 | ≥3.50 | 3.58 ib |

| Absorbing dej tus nqi | ≤ 1.0% | 0.75 ib | |

| Porosity tus nqi | ≤ 4.0% | 2.6 | |

Cov khoom sib piv

| Yam khoom | Tabular Alumina | Dawb Fused Alumina | |

| Cov khoom sib piv ntawm Tabular Alumina thiab Dawb Fused Alumina | Tshuaj muaj pes tsawg leeg ntawm homogeneity | kev sib npaug | Kev nplua yog siab hauv Na2O |

| Qhov nruab nrab qhov pore loj / μm | 0.75 ib | 44 | |

| Porosity tus nqi /% | 3-4 | 5-6 | |

| Qhov ntom ntom / cm3 | 3.5-3.6 | 3.4-3.6 | |

| Kev coj cwj pwm /% | 0.88 ib | 0.04, high-test | |

| Kev ua haujlwm sintering | Siab | qis | |

| Lub zog, thermal shock kuj | Siab | qis | |

| Tus nqi hnav / cm3 | 4.4 | 8.7 ib | |

Tabular & lwm yam Aggregates

Aggregates yog cov caj qaum ntawm cov txheej txheem refractory thiab muab qhov ruaj khov rau cov khoom siv refractory. Cov coarser feem ntau ntxiv thermal shock thiab corrosion kuj thiab aggregate fines optimize particle loj tis thiab ua rau kom cov refractoriness ntawm cov khoom.

Qhov zoo ib yam ntawm Tabular alumina yog qhov tshwm sim los ntawm kev tswj cov txheej txheem sinter zoo nrog rau qhov kub thiab txias tshaj 1800 ° C. Kev siv cov cua kub kub nrog lub xeev-ntawm-the-art technology tso cai densification ntawm cov khoom siv raw yam tsis muaj sintering pab. tsis zoo cuam tshuam qhov kub siab ntawm cov refractories.

Raws li qhov tshwm sim ntawm cov txheej txheem sinter, cov aggregates qhia tib yam mineralogical thiab tshuaj muaj pes tsawg leeg rau tag nrho cov feem. Contrary to fused products where impurities accumulate in the fines, the use sintered aggregates in refractory formulation guarantees ruaj khov thiab txhim khu kev qha tus cwj pwm.

Junsheng muaj ntau qhov sib txawv ntawm cov khoom sib xyaw los ntawm cov feem ntxhib heev rau qhov loj me me ntawm <45 μm thiab <20 μm. Crushing thiab milling yog ua raws li cov kauj ruam de-ironing hnyav uas ua rau cov hlau tsis muaj hlau tsis tshua muaj nyob hauv ntau qhov feem.

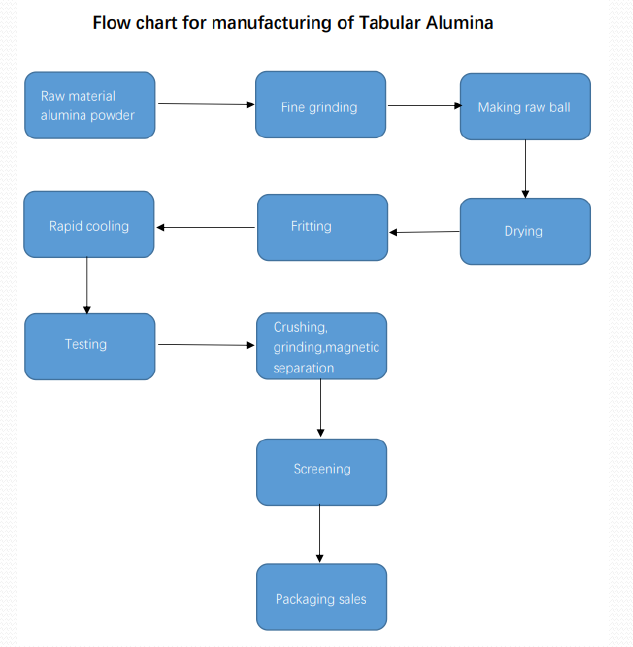

Txheej txheem ntawm Tabular alumina

Raw khoom alumina hmoov

Kev sib tsoo zoo

Ua pob pob

Kev txias txias sai

Friting

Qhuav

Kev sim

Sib tsoo sib nqus sib cais

Kev tshuaj ntsuam

Ntim muag

Daim ntawv thov ntawm Tabular Alumina

Tabular Alumina yog cov khoom ntawm kev xaiv nyob rau hauv unshaped high efficiency refractories siv nyob rau hauv ntau yam industries xws li steel, foundry, cement, iav, prtrochemical, ceramic, thiab pov tseg incineration. Lwm daim ntawv thov uas tsis yog-refractory muaj xws li nws siv hauv cov rooj tog zaum thiab rau hlau pom.