Optimum Toughness Ntawm Cov Grains Brown Fused Alumina, Haum rau Abrasives thiab Refractorie

- Brown aluminium oxide

- BFA

- Brown corundum

Qhia luv luv

Daim ntawv thov

Brown Fused Alumina yog ib qho tawv, ntse abrasives uas tsim nyog rau kev sib tsoo hlau ntawm lub zog tensile siab. Nws cov khoom siv thermal ua rau nws yog cov khoom siv zoo heev rau kev tsim cov khoom siv refractory. Cov khoom no tseem siv tau rau lwm yam kev siv xws li blasting thiab deg hardening.

| Qib | Specification | Tshuaj muaj pes tsawg leeg (F46) | ||||

| Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | ||

| Cib Qib * | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh, Kev nplua | ≥95.2 | ≤1.0 | ≤0.3 | ≤ 3.0 | ≤0.4 |

| Castable Qib | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh, Kev nplua | ≥95 | ≤1.5 | ≤0.3 | ≤ 3.0 | ≤0.4 |

| Vitrified Qib | F12-F220 | ≥95.5 | ≤1.0 | ≤0.3 | 2.2-3.0 | ≤0.4 |

| Resin & Blasting Qib | F12-F220 | ≥95 | ≤1.5 | ≤0.3 | ≤ 3.0 | ≤0.4 |

| Micro Qib | P240-P1200 | ≥92-95 | ≤1.0-1.8 | ≤0.3-0.5 | ≤2.2-4.5 | - |

| F240-F1000 | ≥88-95 | ≤1.0-2.5 | ≤0.3-0.5 | ≤2.2-6.5 | - | |

| Melting point | 2050 ℃ | |||||

| Refractoriness | 1980 ℃ | |||||

| Qhov ceev ceev | 3.90mm / hli3 | |||||

| Mohs hardness | 9.00 Nws | |||||

| Cov khoom | Loj | Chemical Composition (%) | ||||

| Al2O3 | TiO2 | CaO | SiO2 | Fe2O3 | ||

| Ib tug AP1 | F4-F80 P12-P80 | 95.00—97.50 Nws | 1.70-3.40 Nws | ≤ 0.42 | ≤ 1.00 | ≤ 0.30 |

| F90-F150 P100-P150 | 94.50-97.00 Nws | |||||

| F180-F220 P180-P220 | 94.00 – 97.00 Nws | 1.70-3.60 Nws | ≤ 0.45 | ≤ 1.00 | ≤ 0.30 | |

| F230-F800 (P240 ~ P800) | ≥93.50 | 1.70-3.80 Nws | ≤ 0.45 | ≤ 1.20 | ≤ 0.30 | |

| F1000-F1200 (P1000 ~ P1200) | ≥93.00 Nws | ≤ 4.00 | ≤0.50 | ≤ 1.40 | ≤ 0.30 | |

| P1500-P2500 | ≥92.50 | ≤4.20 | ≤ 0.55 | ≤ 1.60 | ≤ 0.30 | |

| AB 和AP2 | F4-F80 P12-P80 | ≥94.00 Nws | 1.50-3.80 Nws | ≤ 0.45 | ≤ 1.20 | ≤ 0.30 |

| F90-F220 P100-P220 | ≥93.00 Nws | 1.50-4.00 Nws | ≤0.50 | ≤ 1.40 | - | |

| F230-F800 (P240 ~ P800) | ≥92.50 | ≤4.20 | ≤0.60 | ≤ 1.60 | - | |

| F1000-F1200 (P1000 ~ P1200) | ≥92.00 Nws | ≤4.20 | ≤0.60 | ≤1.80 | - | |

| P1500-P2500 | ≥92.00 Nws | ≤4.50 | ≤0.60 | ≤ 2.00 | - | |

| AS | 16-220 ib | ≥93.00 Nws | - | - | - | - |

Cib / Vitrified Qib BFA: yog tsim los siv qib tshwj xeeb Bauxite hauv kev tswj fusion tsis. Qib no yog tsim rau Cib / Vitrified cov khoom tiv thaiv Cracks / Fissures, Qhov thiab Dub pob nyob rau hauv cov khoom kawg.

Txheej Txheem Ntau Lawm

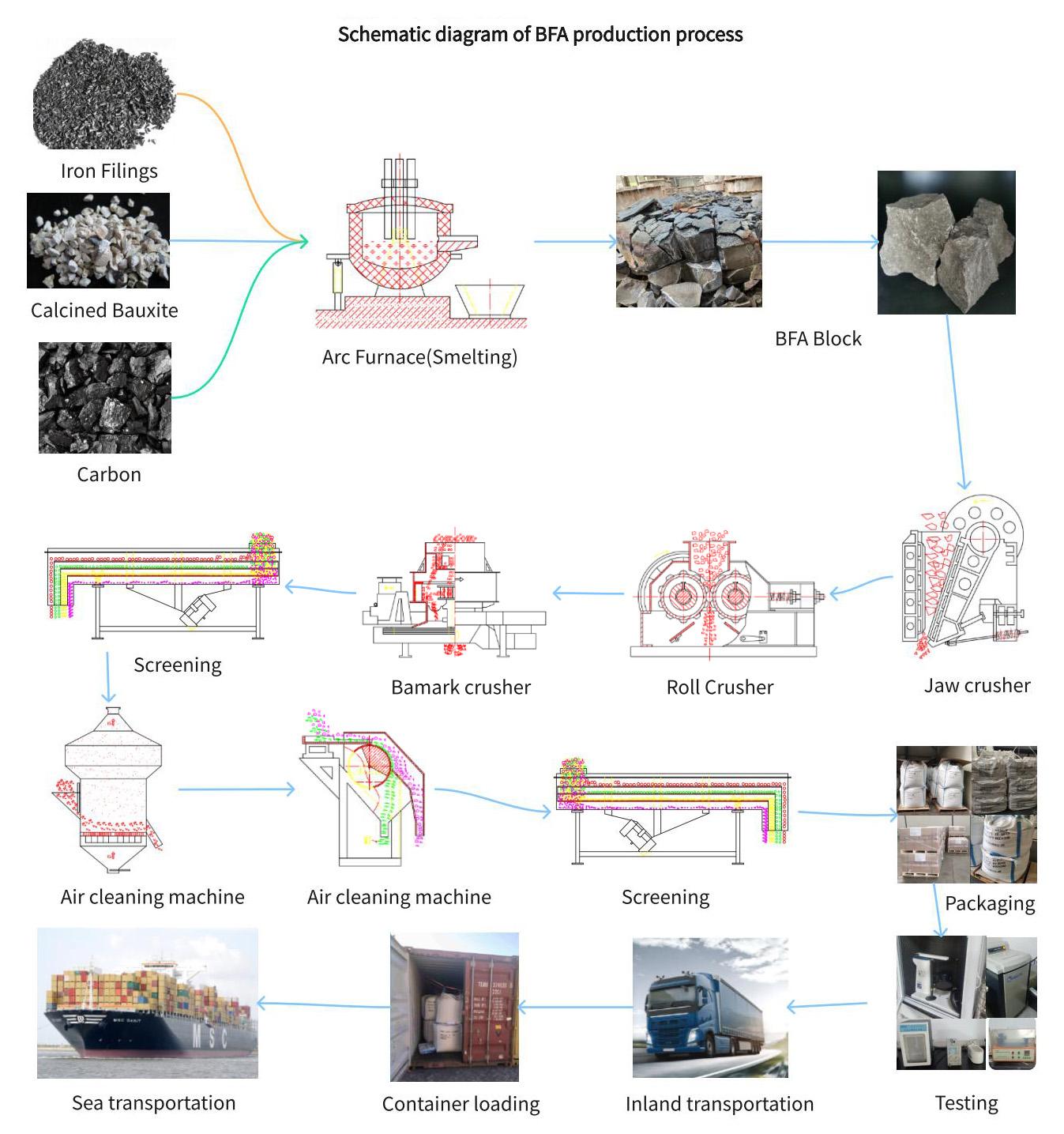

Brown Fused Alumina yog tsim los ntawm smelting ntawm Calcined Bauxite nyob rau hauv ib tug hluav taws xob arc rauv ntawm kub siab tshaj 2000 ° C. Cov txheej txheem ua kom qeeb qeeb ua raws li kev sib xyaw ua ke, kom tawm tau blocky crystals. Lub melting pab tshem tawm cov seem uas muaj leej faj thiab cov pa roj carbon monoxide, Kev tswj nruj ntawm Titania qib thaum lub sij hawm fusion ua kom zoo tshaj plaws ntawm cov nplej.

Tom qab ntawd cov dej txias txias yog ntxiv crushed, ntxuav ntawm magnetic impurities nyob rau hauv siab siv sib nqus sib nqus separators thiab muab faib mus rau hauv nqaim me me feem kom haum rau qhov kawg siv. Dedicated kab tsim cov khoom rau ntau daim ntawv thov.